Area of Collaboration

Characterize and further develop nanocomposite thin film energy storage devices that leverages supercapacitor technology.

Company Background

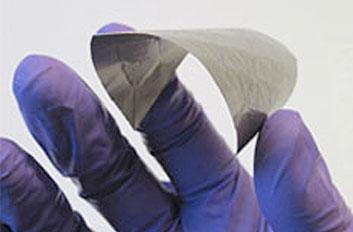

Paper Battery Company, Inc. (PBC) was formed in 2008 and holds a world-wide license to core technology patents developed at RPI. PBC needed assistance to develop prototypes for scalable and conformable rechargeable storage sheets that can be structurally integrated into everyday objects ranging from portable electronic devices to renewable energy and buildings on the grid.

Work with CFES

The Center for Future Energy Systems (CFES) engaged with PBC to carry out wet chemical process development and fabrication of prototype cell structures, and conducted testing and failure analysis of thin film composites. The Energy and Materials Device Lab has a wet process lab and testing facility that includes a fabrication glove box, electrochemical characterization potentiostat for cyclic voltammetry and impedance spectroscopy as well as multi-channel charge/discharge test station for cycle testing. CFES research staff helped develop a process to fabricate prototype cell structures for characterization, along with testing and failure analysis of same.

Impacts of CFES Work

The project results enabled PBC to better understand and develop methodologies to characterize, test and evaluate advanced thin film, nanostructured storage devices and optimize formulations for prototypes. The company has attracted over $7M in private investment to match $1M in NYSERDA grants creating 12 new jobs in the region and relocated its operations to the Rensselear Technology Park. The company continues to reduce to practice these unique thin film storage devices and is evaluating roll-to-roll volume production processes to give high-energy densities at lower cost. CFES is positioned to assist PBC in this process evaluation and continues to work with the company through lab utilization including ESR testing and evaluation of printable thin film production chemistries.